Universal Product Codes (UPCs-GTINs) are essential for effective inventory management, sales tracking, and product identification in retail environments. For companies, determining the number of UPCs requires a systematic approach that considers product variations, changes, and packaging configurations. Here’s a closer look at how businesses can accurately assess their UPC requirements.

Understanding Product Variations

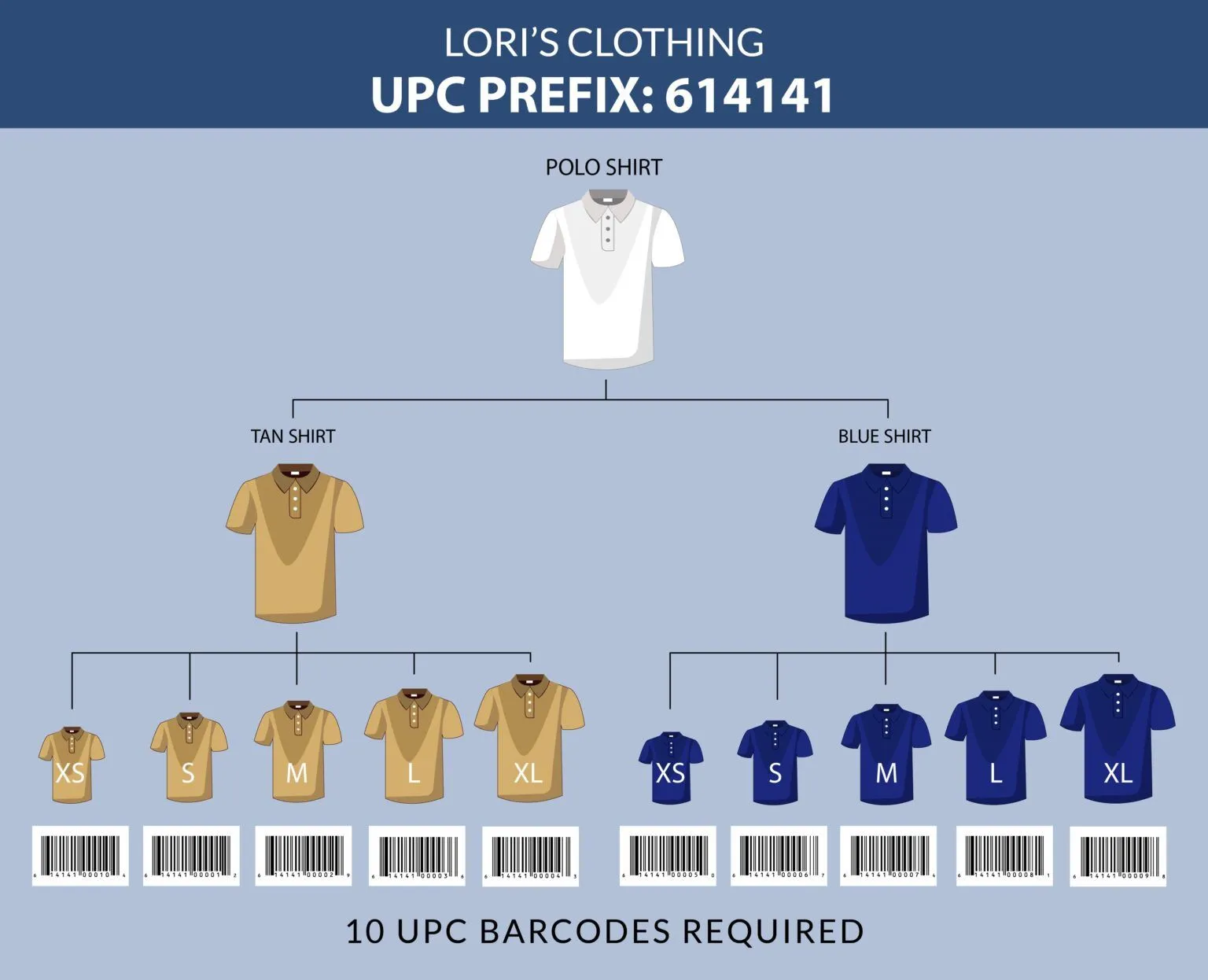

As a general guideline, each variation of a product requires its own UPC. This includes differences in:

- Colors and Patterns: A shirt available in multiple colors will need a distinct UPC for each color.

- Sizes: Each size variation of clothing or footwear must have its own UPC.

- Configurations: Products that come in various forms—like a plastic bottle versus a glass bottle of the same beverage—will also need separate UPCs.

This ensures that stock for each specific item is uniquely identified, facilitating efficient inventory tracking and sales reporting.

Anticipating Product Changes

Companies must also consider potential changes to their products that could impact their UPC assignments. Situations that necessitate a new UPC include:

- Changes in Net Weight: For example, if a snack pack’s weight changes from 7 oz. to 10 oz., a new UPC should be issued.

- Feature Additions: Adding a new feature to a product often requires a new UPC.

- Ingredient Modifications: If a food item becomes gluten-free or has ingredients removed, a new UPC is essential to reflect this change.

Each of these modifications can alter how retailers and consumers view the product, warranting a unique identification code.

Special Considerations for Cartons and Assorted Products

When it comes to shipping, companies that send cartons of the same products can typically use the same UPC for those items. However, if the shipment consists of assorted products, each assortment needs its own unique UPC. This is crucial for accurate inventory management, particularly for retailers who sell bulk items, like warehouse clubs.

For instance, a carton of mixed snacks may require a different UPC than a carton containing only one type of snack. Retailers such as Costco or Sam’s Club may treat bulk cartons as consumer selling units, making it vital to assign distinct UPCs for these configurations.

Apparel and Seasonal Products: A UPC-Intensive Approach

The fashion and apparel industry is particularly UPC-intensive due to the myriad of size and color combinations. Each unique combination must have its own UPC. Additionally, with seasonal rollouts, companies must forecast UPC needs for new items regularly. This ongoing assessment is crucial to ensure that the right UPCs are available as new collections are introduced.

Ongoing Assessment of UPC Needs

Determining UPC needs is not a one-time task. Companies should regularly reassess their UPC assignments—ideally, twice a year. This review should include:

- Current UPC Assignments: Evaluate how many UPCs have been used and for what products.

- Forecasting: Anticipate new product launches or changes that could require additional UPCs.

By staying proactive, companies can avoid running out of UPCs when launching new items or updating existing products.

Partnering for Success

GS1 Barcode Service/Support provides access to experts who can help businesses navigate the complexities of UPC assignments. With support that includes digital files and credits toward barcode testing, partnering with this service makes the UPC assignment process smoother and more efficient.

Conclusion

In conclusion, accurately determining the number of UPCs a company needs involves a careful evaluation of product variations, potential changes, packaging configurations, and ongoing assessment. By taking these factors into account, businesses can ensure that they have the right UPCs in place to support effective inventory management and sales operations. Regular reviews and expert support can further enhance this process, leading to improved operational efficiency.